Microstructure Of High Carbon Steel After Heat Treatment

0 04 to 2 wt to make low medium and high carbon steels.

Microstructure of high carbon steel after heat treatment. The mild steel or called low carbon steel as the main component to through the process of the heat treatment where it containing several characteristic. The general range of mild steel is 0 05 to 0. Heat treatment cycle for steel casting. Microstructure and mechanical properties hardness of en 8 steel after annealing normalizing and quenching.

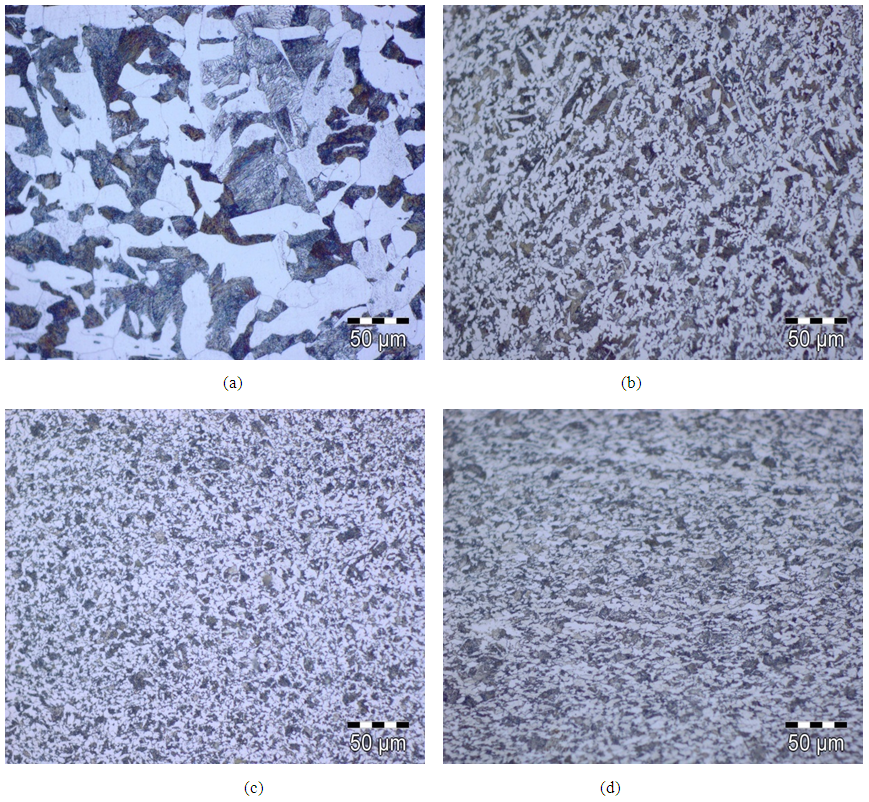

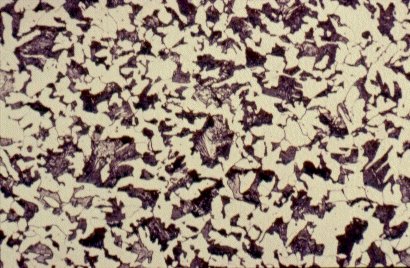

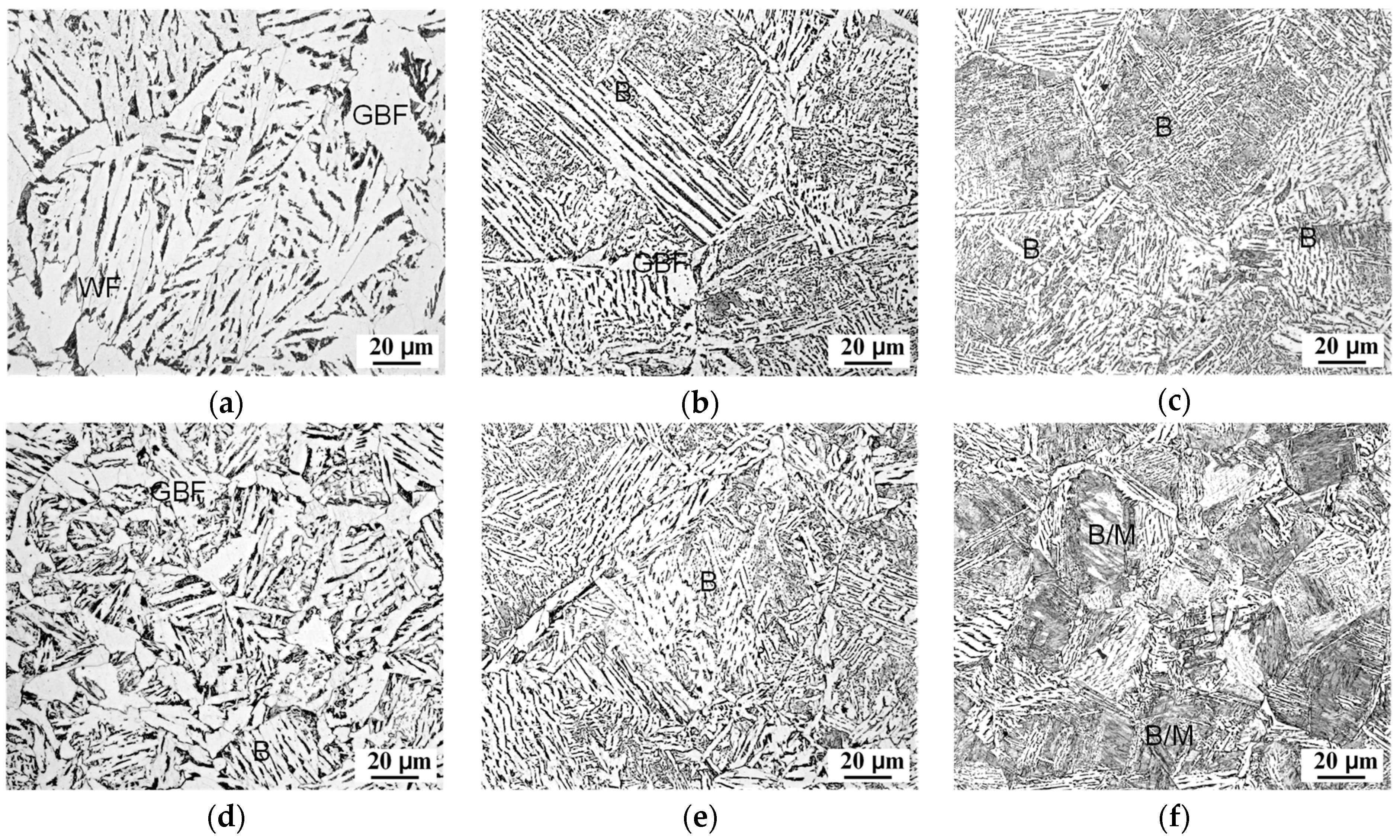

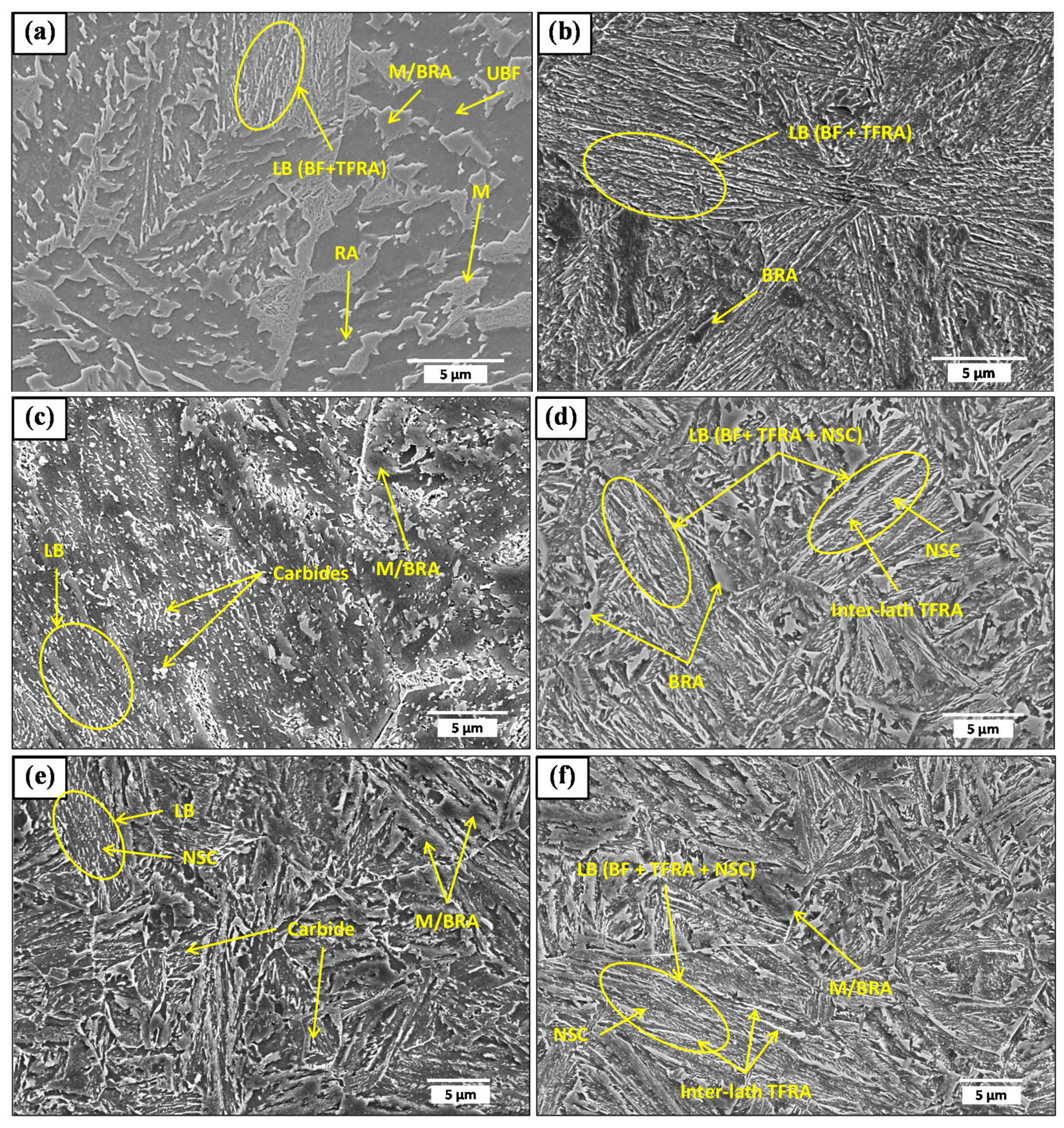

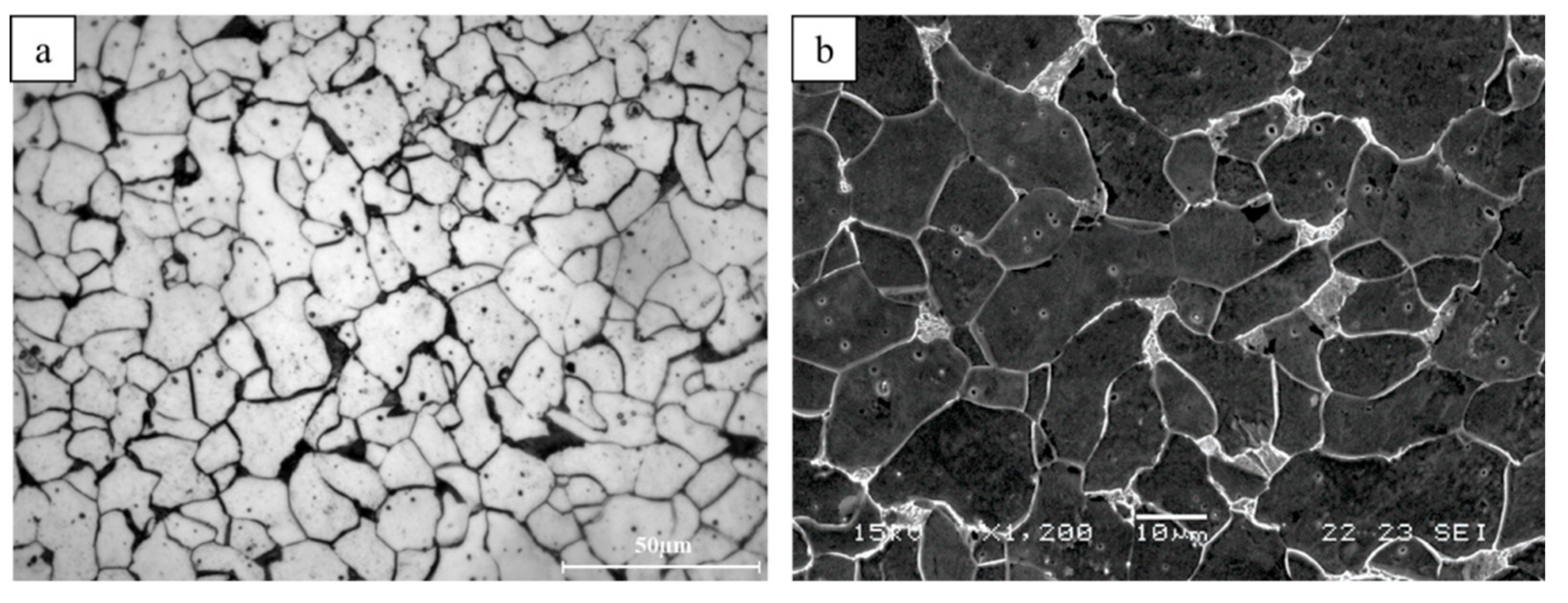

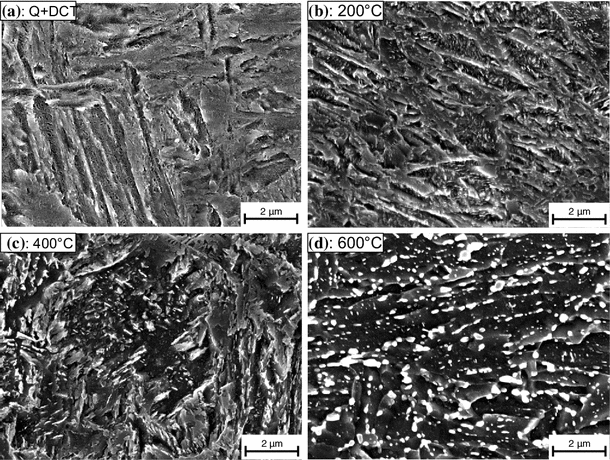

The appearance of an originally pearlitic after a spheroidisation heat treatment at 750 c for 1 5 h courtesy ferrer et al 2005. The objective of the current investigation is to study the effect of post tempering heat treatment on the properties of dual phase high carbon steel. 3 1 effect of heat treatment type on the microstructure of sae 1025 carbon steel the microstructures of sae 1025 steel before and after various heat treatment modes at constant temperature 850 o c and soaking time 1hr are presented in figure 1. Adjusting the carbon content is the simplest way to change the mechanical properties of steel.

The main objective of this research is to study and compare the effect of quenching heat treatment on the absorbed impact energy of low carbon steel medium carbon steel and high carbon steel 5. The microstructure and resulting mechanical properties of these steels are amenable to modification via heat treatment and a wide range of mechanical properties can. Moreover tempering after each heat treatment process is also studied. Radiators cutting tools etc.

Steel steel effects of heat treating. Additional changes are made possible by heat treating for instance by accelerating the rate of cooling through the austenite to ferrite transformation point shown by the p s k line in the figure. In order to research the effect of heat treatment on the microstructure and corrosion resistance of stainless carbon steel bimetal plate the annealing process at 700 xb0 c with different times was carried out for stainless carbon steel bimetal plate. In dual phase high carbon steel if the composition and microstructure are the same.

Because the carbon content of carbon steel was higher than that of stainless steel the carbon would diffuse from carbon steel to stainless. Nevertheless homogenization at high temperature conventional full annealing normalizing and finally tempering are the basic steps in heat treatment of steel casting.