Norton Rubber Grinding Wheel

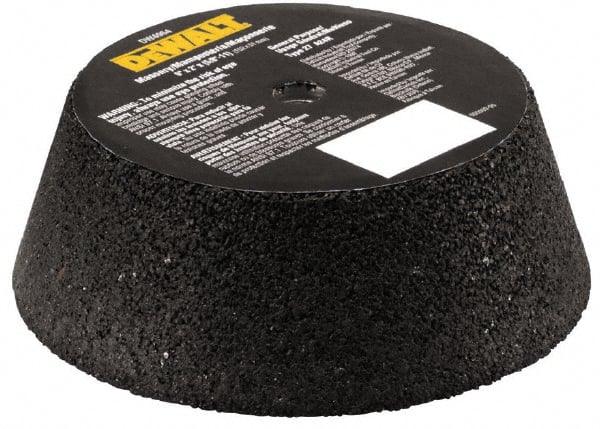

Review our selection include id and bearing wheels cylinder wheels and other shapes.

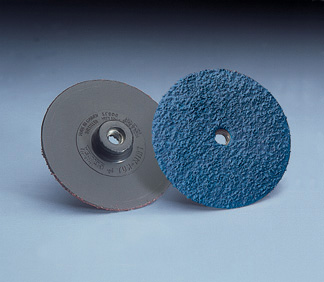

Norton rubber grinding wheel. Lower your total per part grinding costs with our selection of toolroom grinding wheels that deliver precision part quality finishes in many applications. The amounts of each of these grinding wheel components can be adjusted as needed for a given application and together make up a complex and functional composite intended to produce surfaces of interest. 32aa purple wheels are for medium to heavy material removal. The silicon carbide abrasive in these wheels is suspended in rubber for a cushioned grind with light material removal.

They are a blend of aluminum oxide and ceramic aluminum oxide which lasts up to twice as. Norton rubber grinding wheel msc. New norton stellar inserted nut grinding wheels for double and single disc grinding last 30 read more. Norton surface grinding wheels and segments are a universal choice for heavy rapid stock removal and production work to precision tolerance operations.

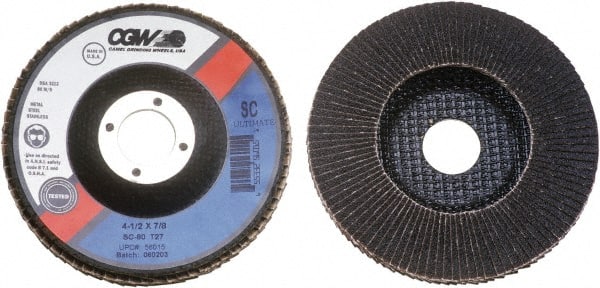

This schematic shows grinding wheel structure showing abrasive grain bond porosity and filler components. A more durable abrasive allows these wheels to remove more material and last longer than norton general purpose grinding wheels. New norton stellar disc grinding wheels deliver excellent surface finishes throughout the life of the wheels while offering improved wheel life increased parts per wheel and lower cost per part. Norton grinding wheels will meet all your rough and precision application needs from aggressive zirconia alumina snagging wheels to precision metallurgical cut off wheels to premium ceramic toolroom wheels with grinding wheels depressed center wheels cut off wheels snagging wheels surface grinding segments mounted points cones and plugs.

They are also known as type 1 wheels and straight wheels. Available to fit many sizes and specification of machines with speed quality and finish in mind. A grinding wheel is a precision tool with thousands of cutting points on its surface abrasive grains that are held in place by a bond matrix hence these are known as bonded abrasives and separated by pores. Our surface grinding wheels come in a variety of abrasive grain types and bonds and can increase grinding performance anywhere from 100 600.

01554229 norton 2 diam x 1 face width medium aluminum oxide coated mounted flap wheel 1 4 shank mount. Grinding wheels for toolroom grinders. A more durable abrasive allows these wheels to remove more material and last longer than norton general purpose grinding wheels. They are also known as type 1 wheels and straight wheels.