Oil Hardening Tool Steel Properties

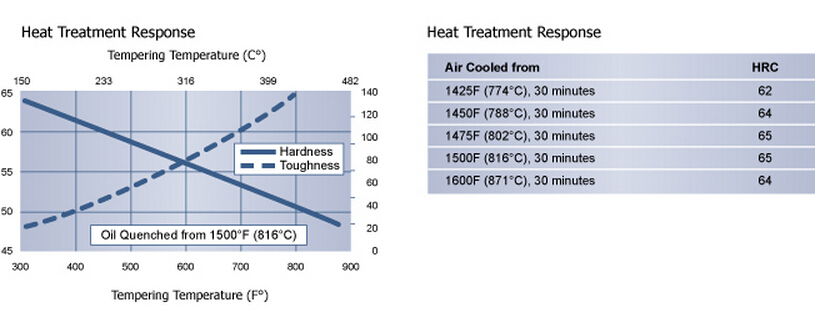

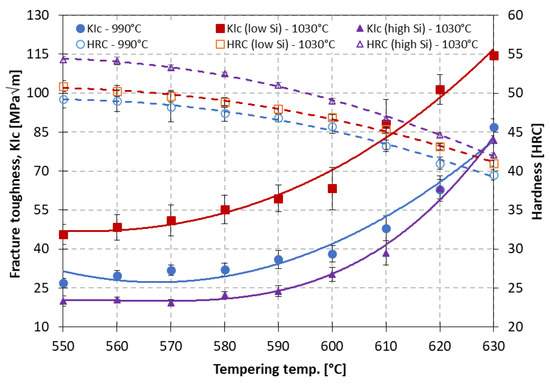

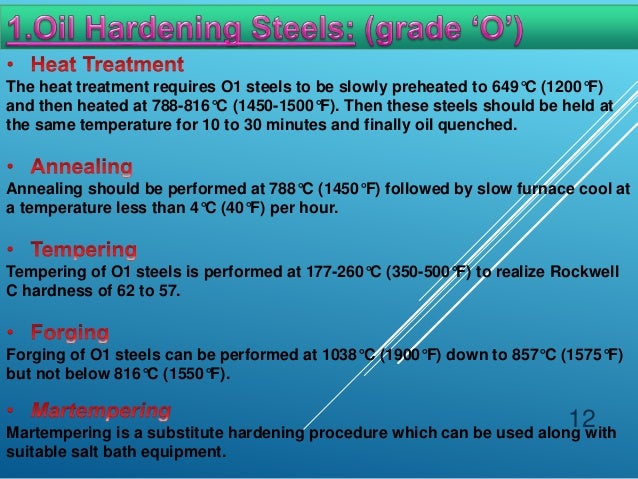

Heat treatment high surface hardness and sufficent toughness after hardening and tempering.

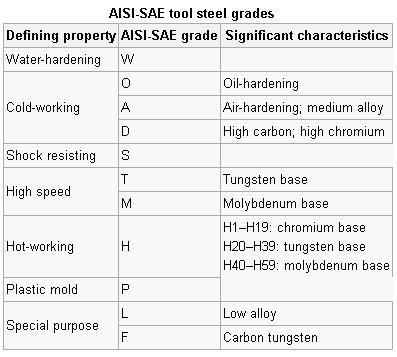

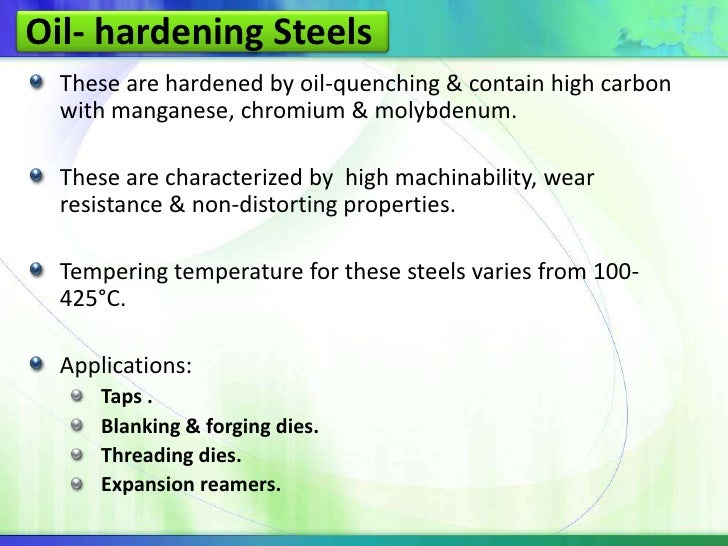

Oil hardening tool steel properties. O1 has a fine microstructure of cementite. The other major tool steel companies made their own oil hardening steels which were all versions of o1 and o2. Cold work tool steels are high carbon steels that are further classified into three subgroups such as oil hardening steels high carbon high chromium steels and air hardening steels. Oil hardening tool steel aisi 01.

Usually when some needs oil hardening steel he probably means aisi o1 cold work steel. Normal care in treatment gives good results in hardening and produces small dimensional changes. This group possesses high hardenability and wear resistance and average toughness and heat softening resistance. Oil hardening steel was very popular with tool and die companies due to the very small amount of warping distortion and size changes the steel would see due to oil hardening.

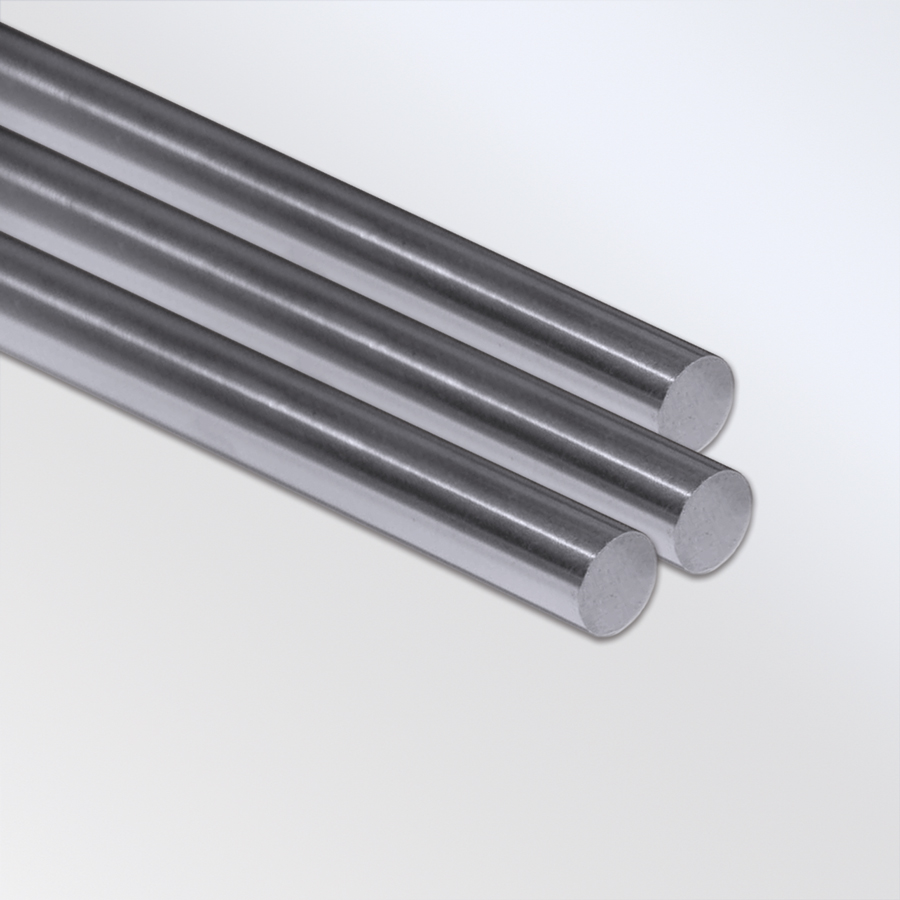

And hardenability good edge holding abrasion resistance and machinability properties dimensionally stable during. Oil hardening o1 tool steel bars with certification. Type o7 oil hardening cold work steel consists of. And you can check full data for aisi o1.

Oil hardening cold work steels are also known as group o steels consisting of o1 o2 o6 and o7 types. These are steels used to cut or form materials that are at low temperatures. All come with a traceable lot number and test report. A2 tool steel is a versatile air hardening tool steel that is characterized by good toughness and excellent dimensional stability in heat treatment a2 is intermediate in wear resistance between o1 oil hardening tool steel and d2 high carbon high chromium tool steel.

It is easy to machine. General purpose oil hardening medium alloyed cold work tool steel with minimum size change high impact strength. Aisi 01 is one of the most well respected oil hardening tool and die steels. Oil hardening cold work steels are also known as group o steels consisting of o1 o2 o6 and o7 types.

It can be hardened to about 57 61 hrc. What is oil hardening steel. Oversized multipurpose oil hardening o1 tool steel bars. The cold work tool steels include the o series oil hardening the a series air hardening and the d series high carbon chromium.

The thickness on these bars is precision ground and held to a tight tolerance. It has good abrasion resistance and sufficient toughness for normal tool and die applications. O1 is a general purpose tool steel that is typically used in applications where alloy steels cannot provide sufficient hardness strength and wear resistance.