Oil Water Separator Design Flow

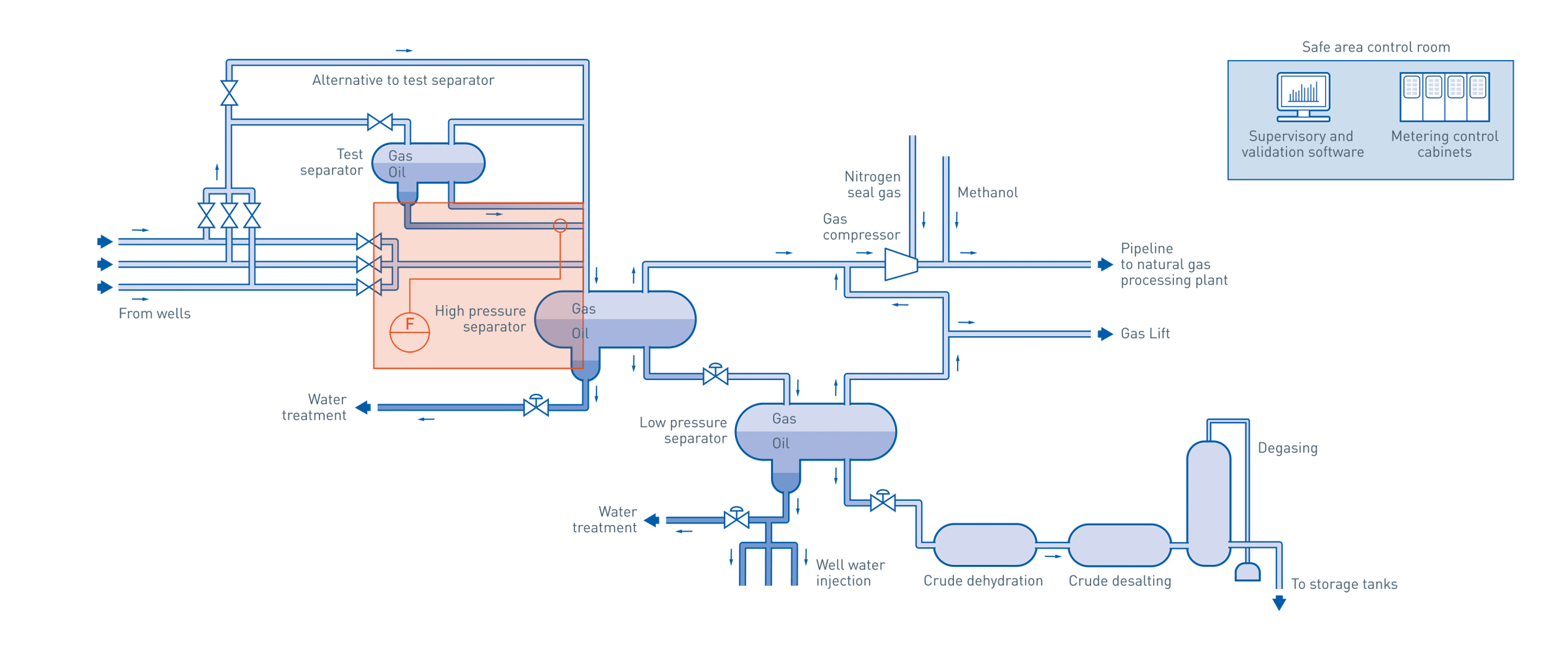

Therefore the effectiveness of any oil water separator is affected by the flow rate.

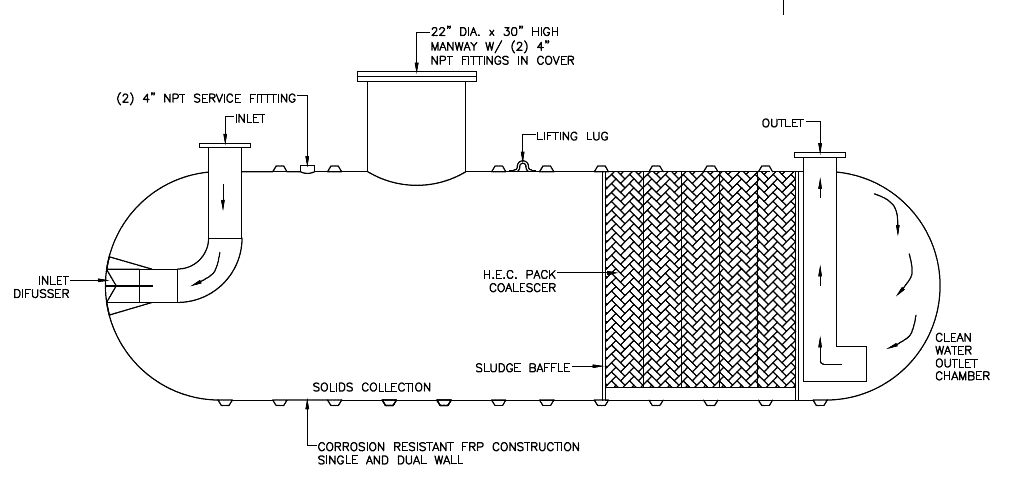

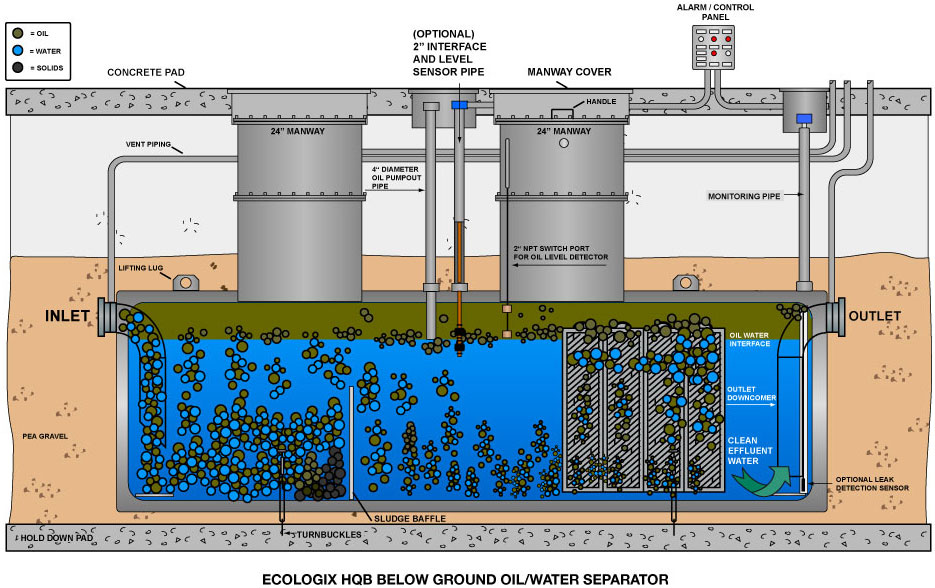

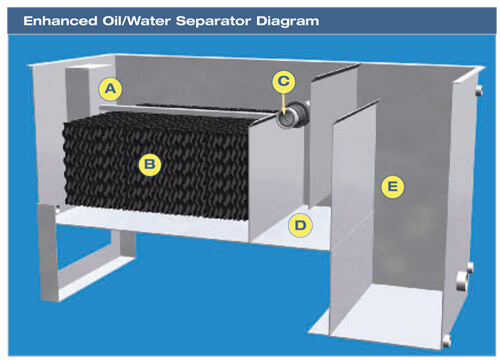

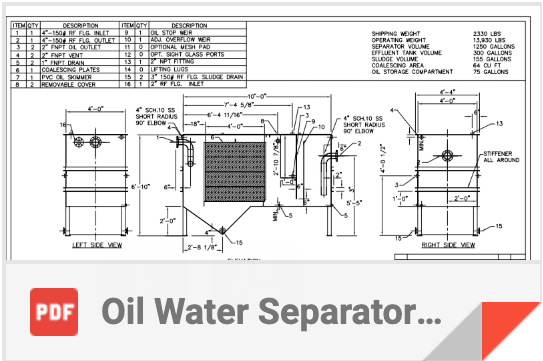

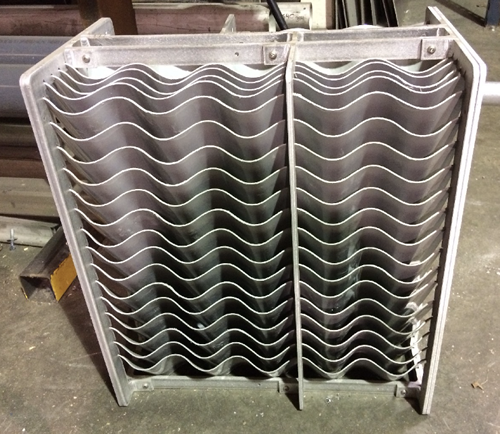

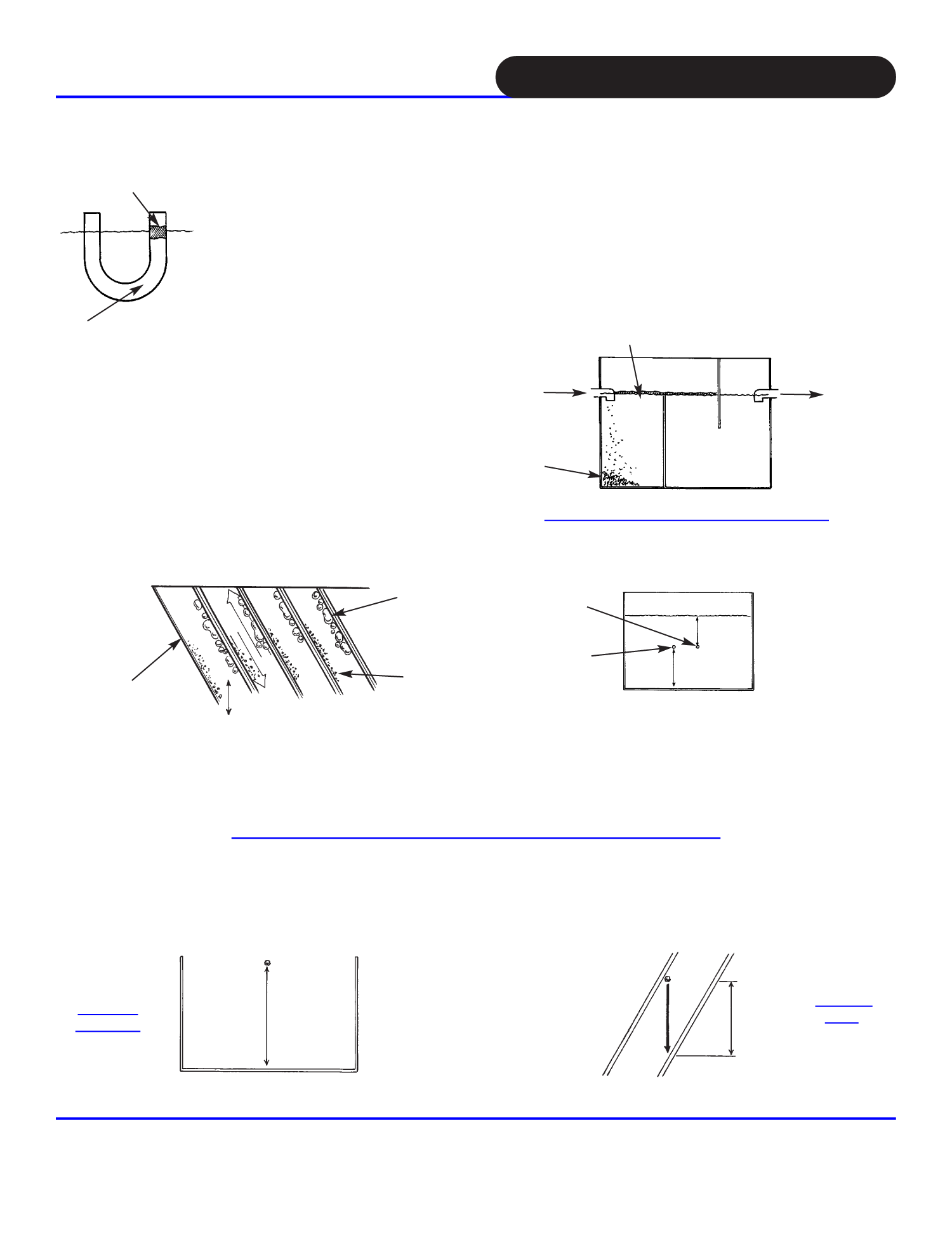

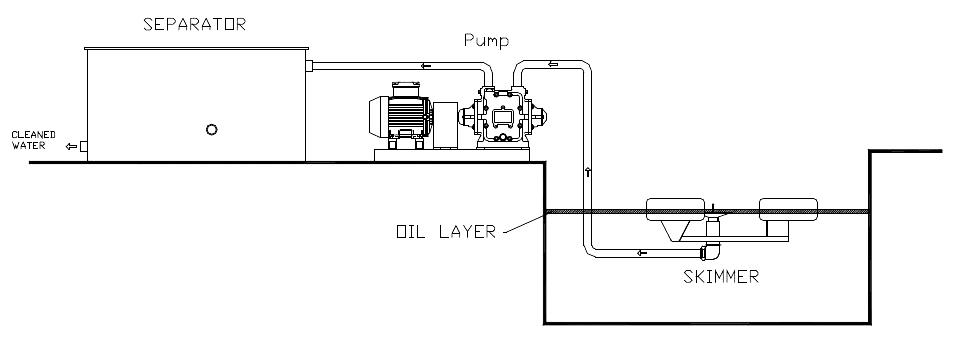

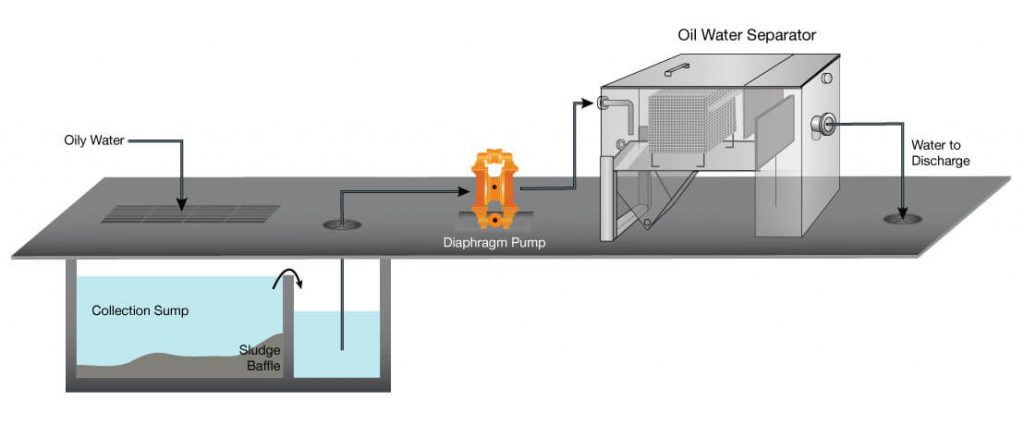

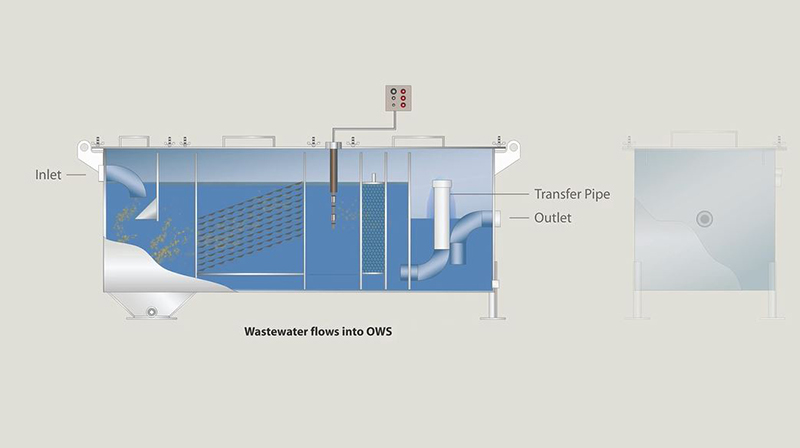

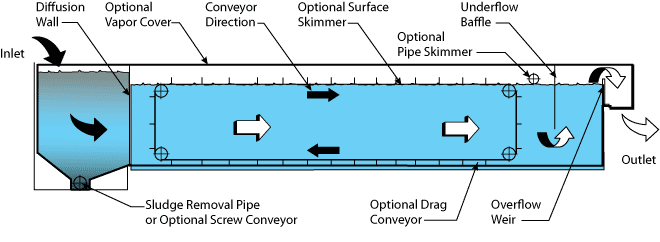

Oil water separator design flow. The slower the flow the better the results. The most common oil water separator design uses parallel corrugated plates that cause the oil droplets. In an oil water separator the oil water mix enters one end and flows toward the other slowly. The design utilizes the difference in specific gravity between suspended solids oil and water buoyancy force enhanced by the use of projected plate surface.

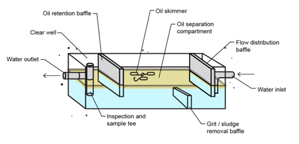

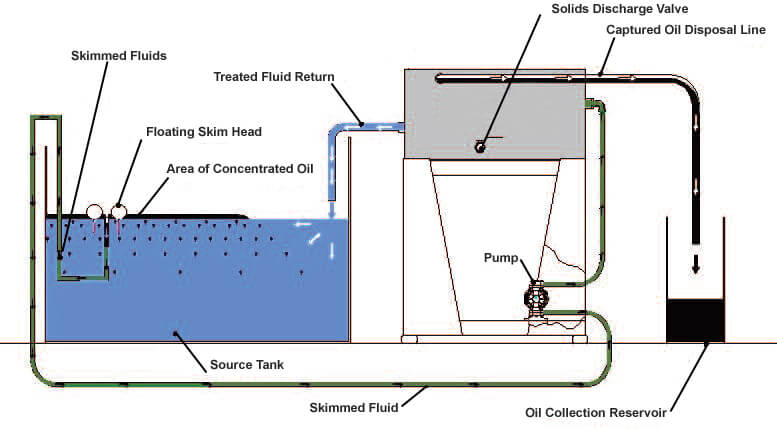

Oil water separators are designed to precipitate and remove suspended solids and essentially all free and dispersed non emulsified oil from an oil water mixture on a once through basis. The forebay is primarily to trap and collect sediments encourage plug flow and reduce turbulence. If the droplet is large enough and the flow down the tank is slow enough laminar the droplet will separate before the end of the tank is reached. The oil separator cell is to trap and hold oil.

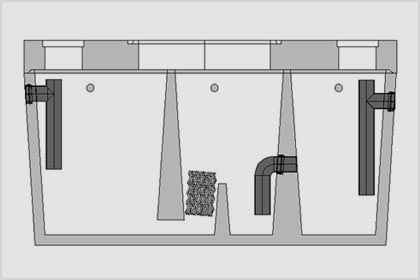

Treatment are flow through separators and are not engaged in a static process. 33 2 1 design oil separators shall be divided into three compartments by baffles or berms. Design considerations for oil water separator systems design of conventional and parallel plate oil water separator systems requires proper characterization of the wastewater establishment of the design flow and required effluent quality sizing of the. A forebay inlet chamber an oil separator cell and an afterbay outlet chamber.

.png)